Priority for Quality Control

Our teams

Our internal research, development and quality assurance teams are made up of passionate and meticulous people. Their recognized expertise is greatly appreciated by our customers.

Our highly qualified personnel are active in carrying out a variety of tests, from the simplest to the most specific, such as measuring the thickness profile of the films, measuring the surface tension with inks tests, determining the strength, sealability and more. Day after day, more than 100 tests and analyses are carried out daily!

At PolyExpert, each batch produced is thoroughly tested to ensure flawless quality, durability and consistency. It is also thanks to these property tests that our technicians prepare the necessary documentation, such as precise technical data sheets and certificates. When a customer requests it, our experts can provide certificates of analysis guaranteeing that the plastic film designed meets the criteria sought. Customer satisfaction is a priority at all stages of the process. Research and development as well as quality control are no exception.

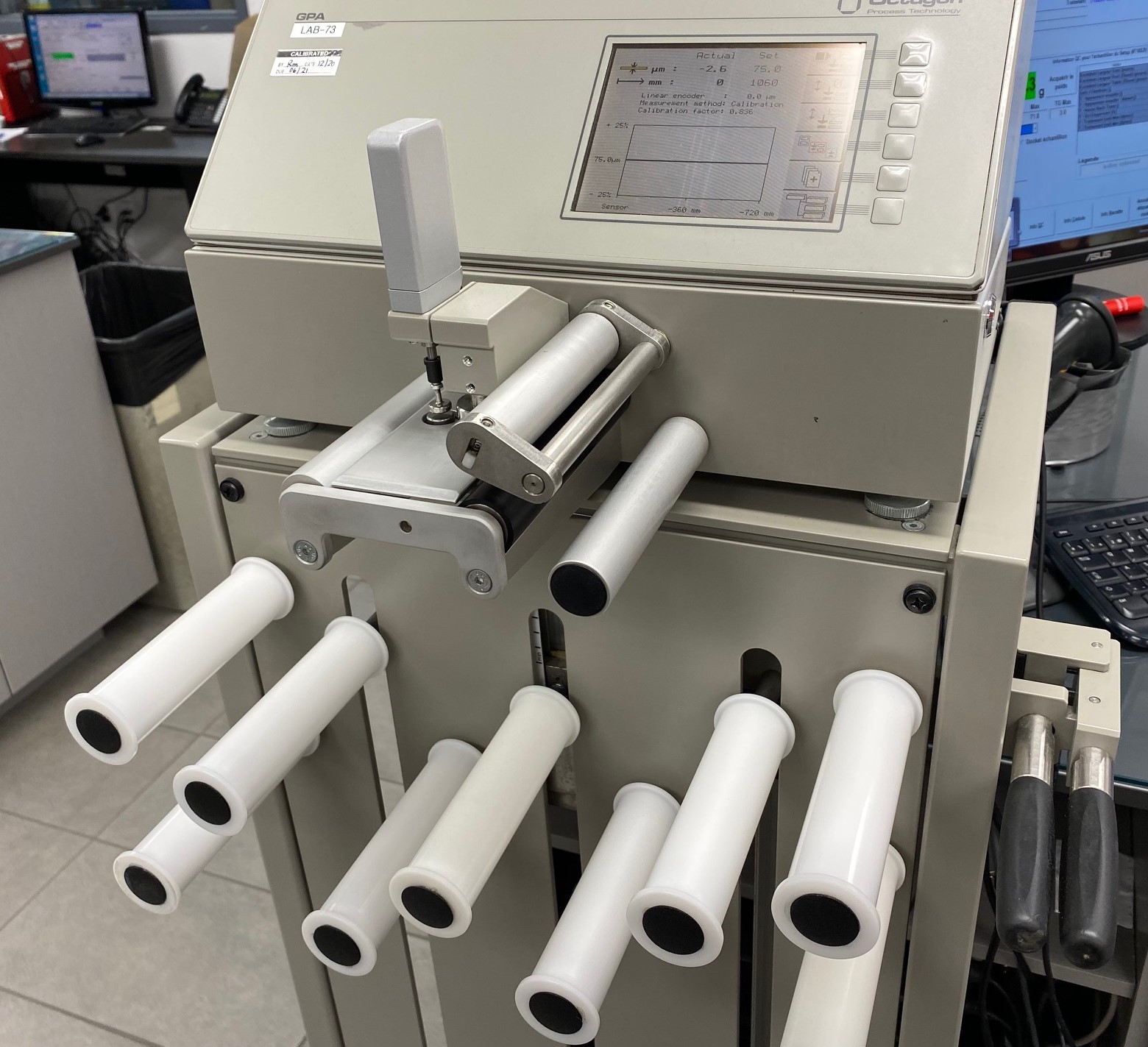

Our Equipment

PolyExpert is proud to have a laboratory and equipment with cutting edge technology. Our most recent acquisition is an IRTF spectrometer, a device that allows us to know the composition of the outer layers of flexible packaging and plastic films. This type of analysis, combined with other techniques and tests, facilitates the work of our research and development team to, among other things, find alternatives to non-recyclable films and offer more eco-responsible solutions.

The wide range of equipment in our laboratory also allows us to analyze your film samples and perform reverse engineering, but also to innovate and develop plastic films with various properties.

How can we help you?

Whatever your plastic film needs, PolyExpert is here for you!

Tell us what you are looking for and we will contact you promptly with recommendations adapted to your situation, deadline and budget.